AUDISON

為了造出―個令人嘆唯觀止、一流的音響系銃,所有的聲音組件都要遵從最高標準的設計,TH系列喇叭正是為THESIS系列功放提供最佳播放效果而沒設計。在過去的幾年中,THESIS的表現無疑印証了其在市場上的高端地位。今天,我們延續了THESIS產品的性能,推出TH系列喇叭,為願客展現絶對完美的音質。

- 經過優化設計的音盆和防塵罩

提供了很好的聲音擴散角度。 - 新特製的紙漿

紙漿中添加了玻璃纖維使得紙盆有很好的強度,使得音質顯得柔和,還保留了紙盆傳統音質的細膩 - 多晶體防麈罩

特殊的原材料保証了防麈罩的剛度和強度。 - 防止共震的鍍鋅網

在不影響音質的情況下保護喇叭。 - 三層波浪橡膠折環

用於頂級高保真家庭音響,此折環的3層波浪設計和材料的選擇確保了聲音的對稱和還原性。 - 對流型冷卻系統

內磁極設有8個通風孔,確保了音圈周圍的空氣對流,性能可靠使其無動態壓縮。 - 鋁質扁平音圈綫

最緊湊的結構加上最輕的音圈重量,單層繞組得到最佳散熱效果。 - 高精度對稱磁路系統

兩個鋁質短路環補償音圈電感。

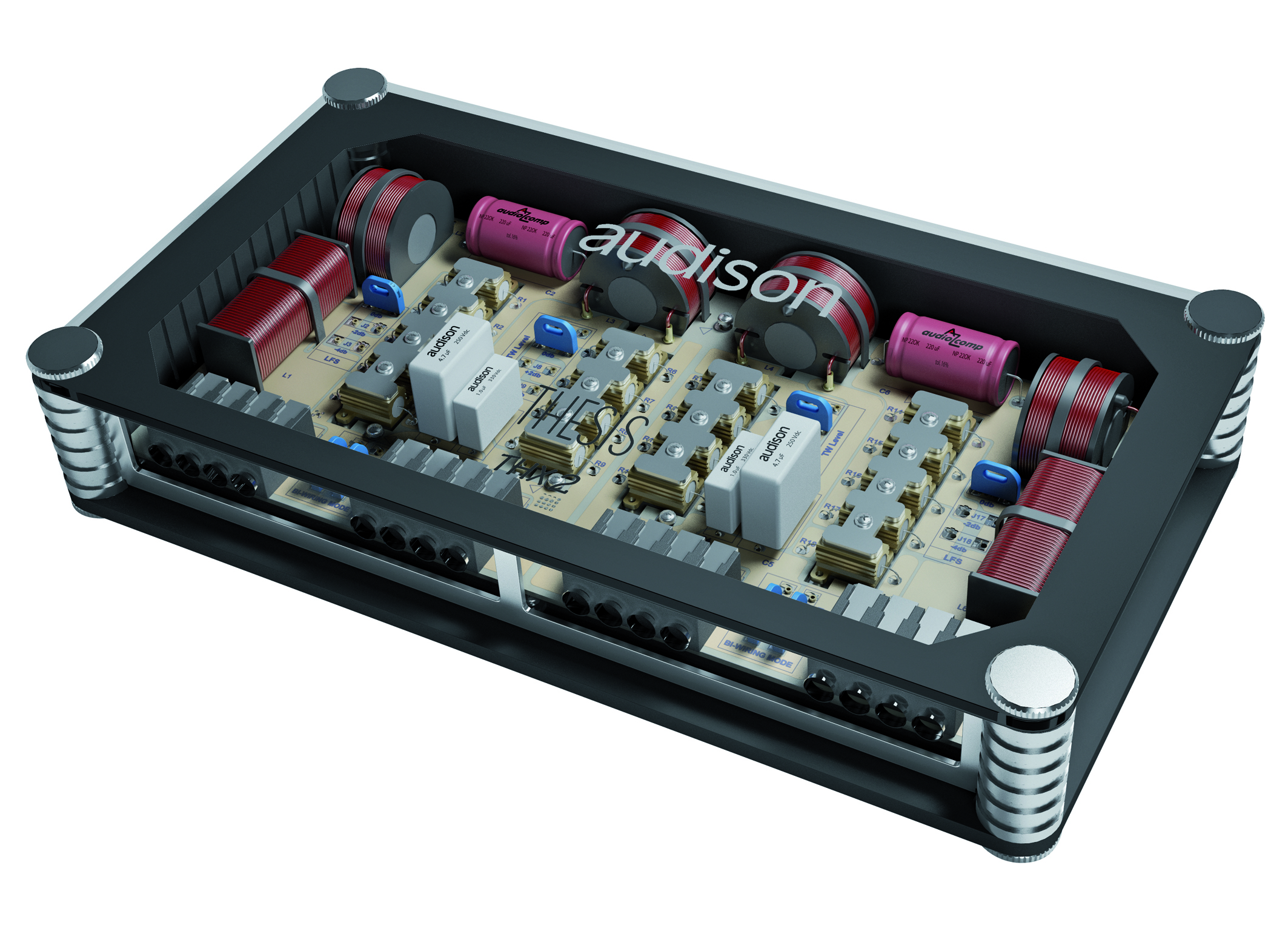

- Robust aluminium chassis: made from aluminium selected for its inert nature against magnetic interferences; features a hidden mounting system.

- Transparent plexi cover: provides a clear view of the internal components.

- Constructed in a mirrored stereo configuration: reduces overall dimensions and mounting time, while making adjustments easier to perform.

- Open Design: to manage all the settings that affect the acoustic results and are used to achieve maximum performance with various speaker positions in any vehicle.

- The electronic circuits: designed for unlimited adjustment versatility, providing limitless customization possibilities.

- 2 mm thick printed circuit board with 105μm copper traces.

- Plate wire wound resistors: housed in an aluminium case secured to the main frame through a mechanical system, increases thermal dissipation capability required for extreme power handling.

- 250 VDC, very low DF, metalized Polypropylene film capacitors.

- Filters and connections are designed to allow multi-amplification configurations.

- Tweeter and midrange sensitivity control: attenuators provide the ability to adjust output emission of each driver for proper system tuning.

- LFS (Low Frequency Shaping): used to shape the low frequency energy, helpful to rectify the peaks and resonances typically found in lower door installations.

- Tuning kit: additional components required for the customization are factory provided.

- Audison Thesis Advisor: an Advanced Manual, offering complete and easy to understand information; along with a professional advisor within the Audison R&D Division, provides support to help users perform the required steps to upgrade their crossover.

For the enthusiasts who prefer to use a passive filter, the R&D team has created THX 2 II, a crossover engineered without compromise with the use of high quality resistors, capacitors and inductors. The filter, for both woofer and tweeter, has special compensation networks that optimize the load seen by the amplifier. The filtering configuration originates from the active Best Envelopment configuration and allows the following fine-tuning options to improve the performance in the passenger compartment:

• 4 emission levels for the tweeter ( -4, -2 , 0, +1,5 dB), designed with L-Pad technique

• mid-frequency level control ( -4 / -2 / 0 / +1,5 dB) centered at 900 Hz to vary the sound character from the analytical one obtained from professional monitors to the softer one typical of the most sophisticated home systems.

• possibility of bi-amplification

TOTAL TRANSPARENCY

The TH 6.5 II Sax was born from a blank sheet with the aim of overcoming all the limits dictated by compromise-oriented design choices. This philosophy allowed us to obtain extreme performance and a design projected into the future, faithful to the inspiring principle of maximum transparency of the musical message.

MAXIMUM LINEARITY, MINIMUM INDUCTANCE, EXCELLENT VENTILATION

The magnetic circuit uses a N48 “H-grade” Neodymium magnet that releases a very high quantity of energy and is ultra stable in temperature, ensuring an unparalleled dynamic. The geometry of the magnetic group has been optimized through a finite element simulation software to maximize efficiency by concentrating the magnetic field in the gap. A great deal of research has been carried out to reduce the modulation of the voice coil inductance by magnetically saturating the motor pole and using an aluminium short-circuit ring that also allows a greater extension towards the mid frequencies.

TOTAL ABSENCE OF MECHANICAL COMPRESSION

The development of the suspension system, a crucial element for each transducer, required a long research work: the development team created computational models to simulate every aspect of the multi-physical behavior of the loudspeaker. The spider was designed thanks to a long series of mechanical simulations performed to define its structure: a large elastic surface with 5 waves, ensuring an improved distribution of the elastic force; waves profile and gluing optimized to obtain the best symmetry in the voice coil and basket connection areas; spider composition made of a mix of two fibers to achieve the best elastic linearity, without mechanical compression effects even at high excursion levels.

Like the spider, the surround was also designed using mechanical simulations. The result is guaranteed by: use of natural rubber IIR; profile optimized to ensure wide excursion; maximization of linear elastic behavior without mechanical compression effects.

TOTAL ABSENCE OF THERMAL COMPRESSION

The 50 mm mobile coil in CCAR (Copper Clad Aluminum Ribbon), wound with flat wire to obtain a very compact winding, maximizes the force factor and at the same time allows for optimal heat dissipation.

TOTAL ABSENCE OF AERODYNAMIC COMPRESSION

The mechanical structure of the TH 6.5 II is a perfect combination of design and performance. The aluminium alloy basket incorporates all the components ensuring high precision in the various couplings. The structure featuring four pairs of spokes allows for solidity and damping of the vibrations offering very low resistance to the cone air flow. The wide spider distributes the elastic load optimally. A generously sized hole, protected by a filter cloth, prevents air compression phenomena under the spider, eliminating deleterious resonance at medium frequencies. The central opening in the bottom-plate ensures optimal decompression of the air column inside the voice coil and the output expanded material diffuses the turbulences and protects it from ingoing foreign bodies.

The human auditory system processes the range of medium frequencies with maximum sensitivity and selectivity because it makes the voice intelligible from the rest of the audio spectrum.

The R&D team started from this simple principle to design from scratch the TH 3.0 II VOCE, dedicated to this fundamental range of frequencies, with the simple as well as ambitious target of extreme linearity, in order not to add or hide anything of the signal reproduced, enhancing in this way every nuance.

ULTRA HIGH CONTROL

The extremely powerful custom N38 “H-grade” Neodymium magnet ensures unmatched control of the mobile group and the aluminium ring nullifies the intermodulation distortion otherwise generated at peak excursions.

EXTREME LINEARITY

Through finite element simulation (FEM) the Audison R&D team has optimized the break-up point between cone/surround, obtaining an ultra-linear frequency response in the mid-range.

The generous 30 mm CCAR (Copper Clad Aluminum Ribbon) voice coil wound with flat wire gives the TH 3.0 II Voce an extraordinary excursion and minimizes at the same time the cone non-linearity.

TPX® CONE

TH 3 II Voce membrane is made of TPX®, a transparent material that ensures frequency response linearity leaving the speaker interior in full view.

TH 1.5 II violino is an extraordinary tweeter featuring a 34 mm CCAW single layer voice coil combining light weight, stability at lower frequencies and total absence of musical transients compression.

The extremely powerful custom N38 “H-grade” Neodymium magnet provides 1.67 T*m in the magnetic gap for superb dynamic response and very low distortion in the whole frequency range.

The exclusive air-loading system resulting in a resonance frequency below 800 Hz, for filter set-up starting as low as 1.5 kHz – 12dB/Oct. The 38 mm natural silk dome has been optimized with extensive material characterization, laser vibrometer scanning and Finite Element Analysis methods for a smooth and extended response. The frequency response is extended up to 26 kHz and is optimized for off-axis installation.

The tuning System featuring two types of electro-acoustic load: bottom case or bottom disk according to targets of highest performance as well as flexibility of in-car integration.

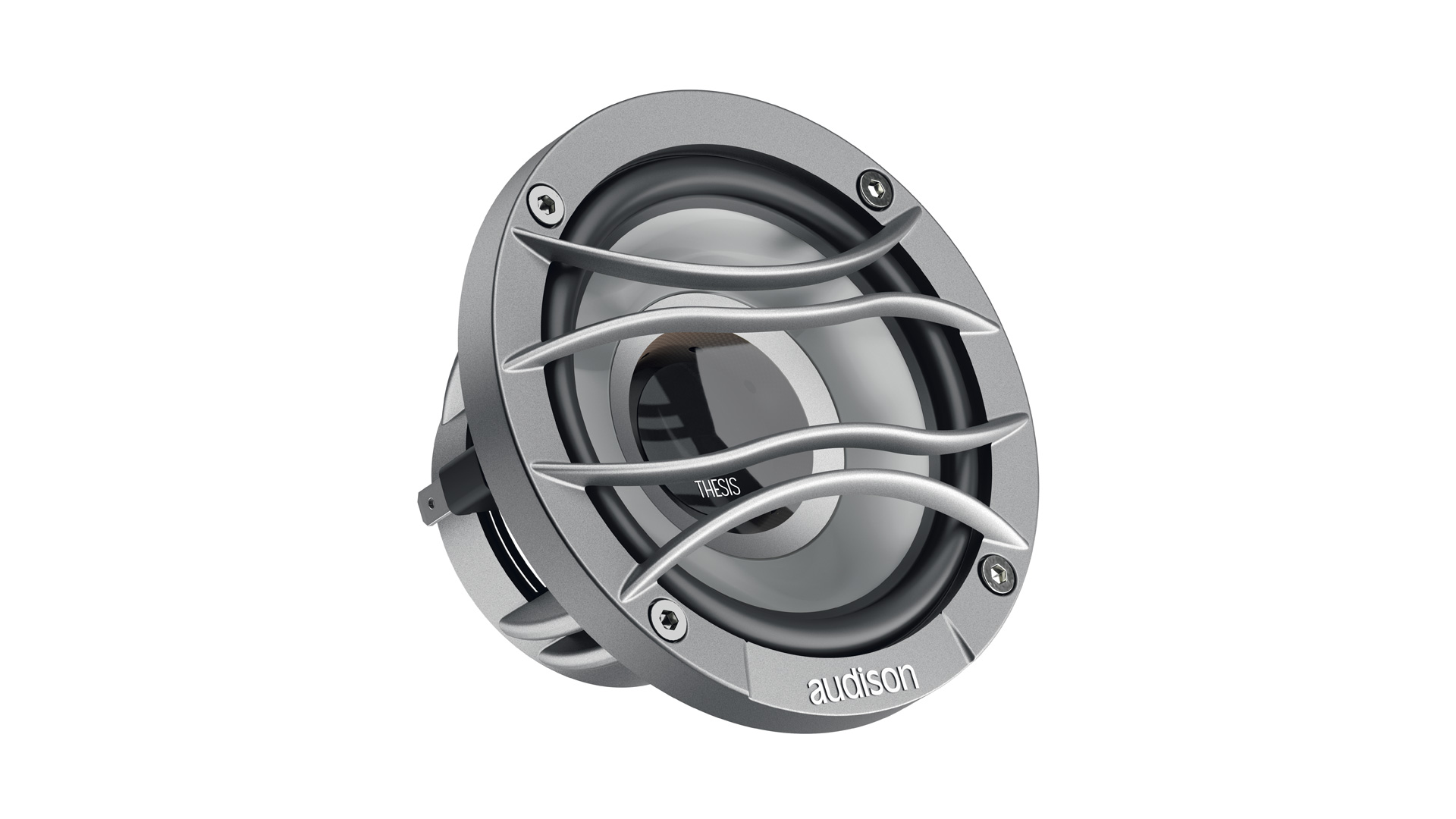

TH 1.5 II violino features a full solid metal construction structure with each part exclusively designed and produced for the Audison TH 1.5 II.

The FEM (Finite Element Method) optimized faceplate and front spokes improve the dispersion pattern. Audison eID technology provides TH 1.5 II traceability starting from the manufacturing stage up to the owner.